FLOATSEAL–

INNOVATVE FLOATING COVER FOR WATER SURFACES!

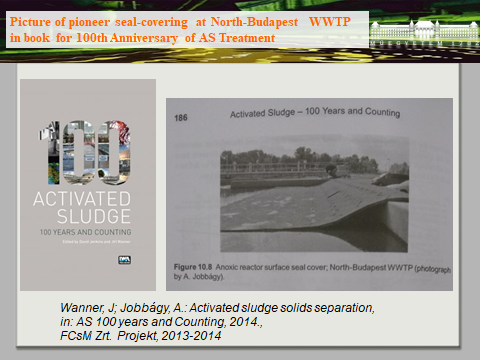

Worldwide novelty of

using floating plastic covers to exclude oxygen penetration in non-aerated

selectors, to increase the effectiveness of removal of nitrogene and phosphorus

and to contribute to good sludge settleability. This innovative method was first

published in 2014 in the volume of „AS

100 Years and Counting ”.

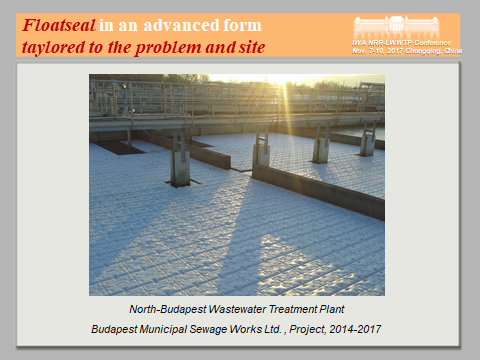

The

Karsai Pécs Co., which is member of the Karsai Holding Plc. in cooperation with

the researchers of Budapest University

of Technology and Economics, Faculty of Chemical Technology and Biotechnology developed

this innovative solution with incremental improvements.

We

have to face the problem of decreasing availability of readily biodegradable

carbon source which is highly needed for

effective removal of nitrate and extra phosphorus. Oxygene penetration further

deteriorate or even prevent the process of denitrification. Traditional

solution to the problem is adding extra carbon or chemicals. With covering the

surface of usually open selectors we create a real anoxic and anaerobic

environment, where the micro-organism can remove the nitrate and extra

phosphorus more effectively and a good sludge is settled. (Jobbágy et. al. (2019) Use of

floating seals to exclude oxygen penetration in non-aerated selectors, Water Science and Technology, 80 (2), pp.

357-364)

-

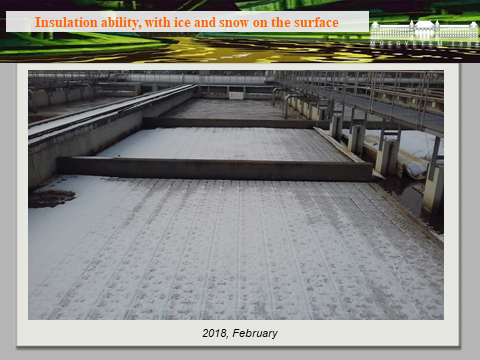

The flloat seal

is designed to provide significant insulation and resist sunshine.

-

The pieces can

be flexibly connected, so you can cover surface of any size and shape.

-

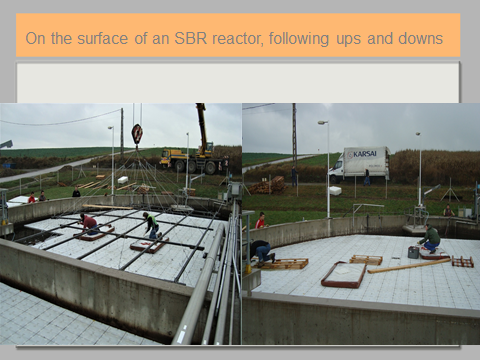

This continuous

float seal surface strictly follows the fluctuations of the water level

-

It is flexible,

lets liquid flowing in and out on the surface and below

-

Resists

different weather conditions, including windstorm, rain, snow or heavy

sunshine; May not sink and be blown by wind.

Features of a float seal:

-

size :

400 x 400 x 50 mm

-

weight

:

0,97

kg per unit

-

material :

polypropylene

-

color:

white

Temperature: between - 20 C and + 46 C

Special applications:

-

cost-effective operation of biological wastewater treatment

-

providing real

anaerobic and anoxic conditions for biological P and N removal.

-

contributing to

well-settling activated sludge

-

hindering exit

of unpleasant

odor

Advantages :

-

cost-effective

-

environment friendly solution; makes chemical savings possible

-

saving and fermenting C-source

-

decreasing the likelihood of N2O formation, being responsible for

global warming and green-house effect

-

excluding snow

and sudden temperature decrease

-

suitable for

covering any liquid surface like reservoir, tank, pond etc.

Contact:

Katalin Hubay

Mail: hubay.katalin@karsai.hu

Tel.: +36-30/300-6527